Automation & Robotics Engineering Technology (AURO)

Department of Applied Engineering, Safety & Technology

Prepare for in-demand, industry-focused careers in automation and robotics with Millersville University’s hands-on 2-year Associate of Technology in Applied Engineering & Technology - Control Systems Technology (CSYS) or 4-year Bachelor of Science in Automation & Robotics Engineering Technology (AURO). Both degrees provide 21st-century skills and abilities to design, develop, integrate, and innovate cutting-edge control and robotic technologies that will automate the future!

Interested in Automation & Robotics Engineering Technology? Request more information

Automation & Robotics Engineering Technology

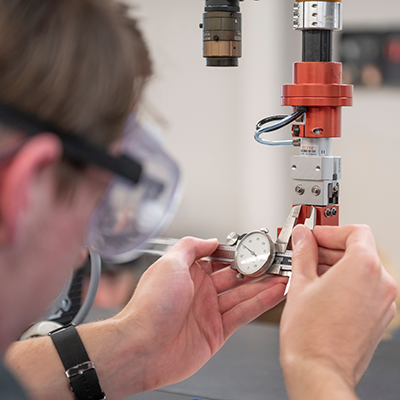

Hands-on experience integrating automation, robotics, control engineering, and computer science.

Automation & Robotics Engineering Technology (AURO)

Bachelor of Science (4-year, typ)

The 4-year B.S. in Automation & Robotics Engineering Technology (AURO) program provides students with a strong foundation in engineering principles, electronics, control systems, mechanical systems, software development, and system integration for robotics and automation. Through hands-on design, programming, and system integration, students gain practical experience in modeling, simulation, and automation of process control systems.

The 4-year B.S. in Automation & Robotics Engineering Technology (AURO) program provides students with a strong foundation in engineering principles, electronics, control systems, mechanical systems, software development, and system integration for robotics and automation. Through hands-on design, programming, and system integration, students gain practical experience in modeling, simulation, and automation of process control systems.

BACHELOR'S DEGREE Catalog Listing

Gateway Pathway Model for AURO Majors Starting Fall 2026

Legacy Pathway Model for AURO Majors Enrolled Prior to Fall 2026

“MU did a great job preparing me for the challenges I face in my career. The expectations of the professors and their drive to develop “out of the box” and analytical thinking skills are what I believe to be one of the biggest takeaways. The individualized attention that the professors provide is invaluable when developing the necessary skillsets required for the real world.”

- Gilbert Ramos | 2014

Control Systems Technology (CSYS)

Associate of Technology (2-year, typ)

The 2-year A.T. in Applied Engineering & Technology - Control Systems Technology (CSYS) program equips students with the technical expertise to troubleshoot, maintain, and program automation systems. Through hands-on laboratory-based coursework, students develop systems thinking and troubleshooting skills to diagnose, integrate, and enhance control systems. Emphasizing real-world implementation and system reliability, the program prepares graduates for careers in automation and control systems.

ASSOCIATE'S DEGREE CATALOG LISTING

Minor in Control Systems Technology

A minor in Control System Technology is available to students who complete 18 credits of technical courses related to the study of Robotics and Control Systems.

Don't leave your question unanswered.

Don't leave your question unanswered.

Dr. John Haughery is the program coordinator for the Automation & Robotics Engineering Technology degree in the Applied Engineering, Safety & Technology department. He will be able to answer any question you have about the AURO program or any of the other programs in the department.

View Dr. Haughery's Contact Information

Print out your own copy of the AURO program information by clicking on the icon to the left or use the button below.

Top three reasons to study automation & Robotics Engineering Technology AT MU:

- Learn relevant, in-demand automation, robotics, artificial intelligence, computer programming, and control system engineering skills.

- “[The] demand for robots has never been stronger as more industries look to automation to increase productivity and alleviate ongoing labor shortages”

- Earn one of the highest starting salaries after graduation from the university: automation/controls/robotics engineers $65,000- $75,000 per year.

MAKE YOURSELF MORE EMPLOYABLE, CONSIDER AN INTERNSHIP:

Students are encouraged to participate in industrial internships to gain valuable, real-world experience that complements their academic and technical preparation. Internship opportunities span areas for management, industrial and mechanical design, graphic design, 3D modeling and printing, technical illustration, and packaging design and prototyping. Many internships include significant management components, with responsibilities in planning, organizing, directing, and supervising workplace activities. The student, employer, and AEST faculty work collaboratively to ensure each internship provides the highest possible learning value—both in technical skills and professional development.

Laboratory Facilities for AURO Majors:

There are multiple laboratory facilities dedicated to supporting the Automation & Robotics Engineering Technology degree. Some of the laboratories include:

There are multiple laboratory facilities dedicated to supporting the Automation & Robotics Engineering Technology degree. Some of the laboratories include:

- Adaptive Computing

- Automation/Controls

- Advanced CADD

- Electronics

- Fluid Power

- Robotics R&D

- Intelligent Machines

- Materials Processing

- Rapid Prototyping

We use RoboDK (robotdk.com) for simulation and offline programming of industrial robots.

Clubs & Activities

'Ville Robotics - Association of Technology, Management & Applied Engineering (ATMAE) Student Chapter (aka MU Robotics Team) The MU Robotics Team has earned 50+ awards since 2001 in national or international robotics competitions. The team boasts seven national robotics championships.

Pictured: 2023 Intelligent Ground Vehicle Competition team photo.

Robotic WorX is an industry-aligned program designed to spark student interest and provide hands-on experience solving real-world robotics, automation, and advanced manufacturing problems. The program helps address pressing workforce and process challenges by developing proof-of-concept solutions through student-industry collaboration. Find out more here

Epsilon Pi Tau (EPT) – Beta Phi Chapter. Epsilon Pi Tau is an international honor society for professions in technology. At Millersville, this includes Technology & Engineering Education, Applied Engineering & Technology Management, and Occupational Safety & Environmental Health majors.

-

Job titles of recent AURO Graduates

Job titles reported by recent AURO GraduatesWhen Automation & Robotics Engineering Technology graduates complete their studies at Millersville University, they embark on careers that have limitless potential. Here are some of the job titles Automation & Robotics Engineering Technology graduates reported in a 2021 survey of recent department graduates:

- Application Engineer & Product Specialist

- Assembly Engineer

- Automation Engineer

- Automation General Manager

- Automation Programmer

- Automation Specialist

- Certified Machinery Safety Expert

- Control System Engineer

- Design Engineer

- Engineering Supervisor

- Engineering Technician

- Industrial Automation Engineer

- Installation Supervisor

- IT Project Specialist

- Lead Systems Engineer

- Manufacturing Engineer

- Plant Service Engineer

- Process Control Engineer

- Process Engineer

- Product Design Engineer

- Product Manager

- Program Engineer

- Project Engineer

- Project Manager

- Quality Manager

- Robotics/Automation Engineer

- Sales Engineer

- Sales Representative

- Site Supervisor

- Software Application Engineer

- Solution Engineer

- Sr. Engineer

- Support Engineer

- Team Supervisor

- Validation Lead

- Vice President Sales & Marketing

-

ATMAE Accredited Program

Degree: Bachelor of Science

Program Name: Automation and Robotics Engineering Technology

CIP Code: 15.0406

A program that prepares individuals to apply basic engineering principles and technical skills in support of engineers and other professionals engaged in developing, installing, calibrating, modifying and maintaining automated systems. Includes instruction in computer systems; electronics and instrumentation; programmable logic controllers (PLCs); electric, hydraulic and pneumatic control systems; actuator and sensor systems; process control; robotics; applications to specific industrial tasks; and report preparation.

Program Mission Statement:

The AURO program seeks to 1) deliver a rigorous, hands-on curriculum grounded in engineering principles, modern industrial control systems, and advanced robotics and programming to prepare students for successful careers in automation engineering, 2) develop graduates with technical expertise, problem-solving ability, and agility to lead in dynamic, technology-driven industries, and 3) engage industry, education, and community partners to strengthen workforce development and expand career pathways into automation engineering.

Program Description:

The Bachelor of Science in Automation & Robotics Engineering Technology (AURO) introduces students to the fundamentals of power, electronic systems, and formal programming techniques common in industry. The curriculum, supported jointly by the departments of Applied Engineering, Safety & Technology and Computer Science, includes in depth technical content of electronics, control systems, mechanical systems, and computer programming and applications to prepare professionals equipped to design, improve, maintain, and manage robotic and automated process and control systems. Laboratory courses require students to design, program, develop and construct projects independently and in small teams. -

Schedule a visit to Applied Engineering, Safety & Technology

University Open House Days and Personal Tours Available. The best way to get to know us is to come and see us!

The best way to get to know us is to come and see us!Millersville University offers several opportunities throughout the year for you to visit campus and explore our academic programs, student life, financial aid, and the application process. You can find upcoming University Open House dates on the Admissions Department webpage.

We’re also happy to meet with prospective students and their families outside of scheduled open house events. Please contact us using the email or phone number below, and we’ll arrange a visit and connect you with a professor who specializes in your area of interest.

Email: AEST@millersville.edu

Phone: 717-871-7237 -

AEST News Blog and Department Information

Keep up on the latest things happening in and around the Department of Applied Engineering, Safety & Technology. You can see what the students and staff are doing right now.

Always know what's happening by reading the AEST News

-

Osburn Hall Building Hours

Office Hours:

7:30 a.m. - 4 p.m. Monday through Friday

Building Hours:

7:30 a.m. - 10 p.m. Monday through Thursday

7:30am - 4:30 p.m. Friday